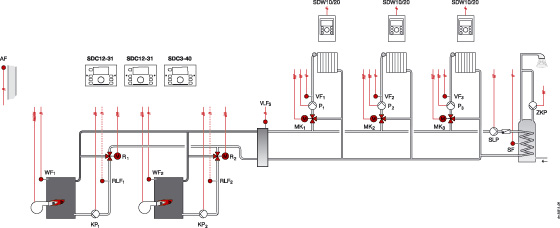

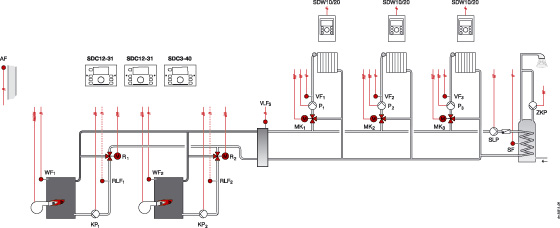

2x Boiler 2 stages, 3x mixed circuit, DHW

| • |

Boiler series control for two boilers (two-level) and three mixed circuit controllers along with one hot water controller |

| • |

The correct function of boiler series control depends on the appropriate pairing of the controller and hydraulic system. Therefore the consumer circuits should be decoupled from the two boilers using a hydraulic by-pass. |

| • |

Note: System no. 305 means that certain parameters must be set for this application to function. |

|

| Mixed heating |

3 circuits |

| Domestic Hot Water |

2 pumps |

| Boiler |

2x 2-stage |

| Returncontrol boiler |

yes |

|

| Functions |

| • |

The basic functions are contained in an indestructible program. |

| • |

All the parameters are predefined with sensible basic settings and allow individual adjustments as necessary. PCs are not required for this. |

| • |

All the relay outputs can be tested manually. |

|

| Boiler control |

| • |

Boiler series controller for one or two-level burners |

| • |

Constant minimum limit of boiler temperature |

| • |

Maximum limitation of boiler temperature |

| • |

Minimum burner switch-on and switch-off times |

| • |

Operating hours recording for each burner level |

| • |

Replacement of the pilot boiler, depending on time and external temperature |

| • |

Blocking of next boiler, depending on external temperature |

|

| Heating circuit |

| • |

Time switch for daily, weekly and holiday programs for each heating circuit |

| • |

Optimisation of switch-on times |

| • |

Caretaker function, frost protection function |

| • |

Outdoor temperature-compensated heating circuits, with room tie-in as necessary |

| • |

Min./max. limiting of flow temperature |

|

| Hot water control |

| • |

Time switch with daily and weekly program for hot water filling pump |

| • |

Anti-legionella automatic system |

| • |

Hot water priority circuit |

| • |

Outdoor temperature-compensated parallel operation |

|

| Combination |

| • |

Combination option of up to five freely-selectable SMILE controllers |

|

| Communication |

| • |

Communication takes place over the system bus without additional interfaces |

| • |

Distance (max. 100 m) |

| • |

All the data required for the control system is communicated |

| • |

Remote operation with the wall modules SDW.. also takes place using the system bus |

|

| Fault message |

| • |

If the required temperatures cannot be achieved within a reasonable time, or sensors interrupt or short-out, then the controller will generate a fault message. |

|

| Description | Additional Product Type |

|---|

| With connection base for wall installation | SDC3-40WM |

| With connection base for wall installation (2) | SDC12-31WM |

| With connectable terminal strips for control panel installation | SDC3-40PM |

| With connectable terminal strips for control panel installation (2) | SDC12-31PM |

| Description | Additional Product Type |

|---|

| Outside air temperature sensor | AF20 |

| Contact temperature sensor VF (3) | VF20A |

| Boiler, boiler return, hot water and strategy temperature sensor (without well) WF, RLF, SF, VLF (6) | KTF20 |

| Description | Additional Product Type |

|---|

| Remote control with temperature selector/sensor and mode switch (3) | SDW10WE |

| Description | Additional Product Type |

|---|

| Immersion temperature sensor (instead of VF20A) | VF20T |

| Hot water sensor with NIRO immersion well (instead of KTF20) | VF20LN |

| Easy-to-use remote operation with display and complete programming unit along with temperature sensor/selector (instead of SDW10) (3) | SDW30 |

| Base for Smile Controller, for control panel installation as touch protection | SCS-12 |

| Connecting base for wall installation of SMILE panel models | SWS-12 |

| Reducing attachment frame for control panel installation, assuming available control panel cut-out on controllers

ZG52 /53 /55 / 82 /85 or

ZG215 /215V /252 /254 | SRR |